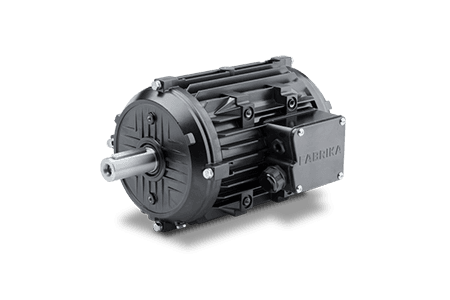

Find out about Our Dedication to Excellence in Cooling: How We’re Shaping the Future with Every Fan

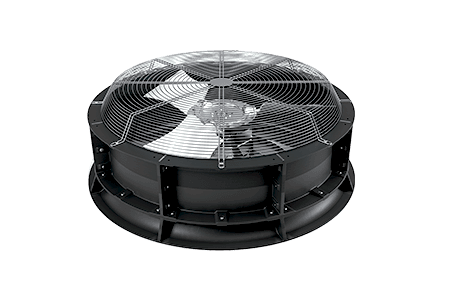

Axial Fans for HVAC/R

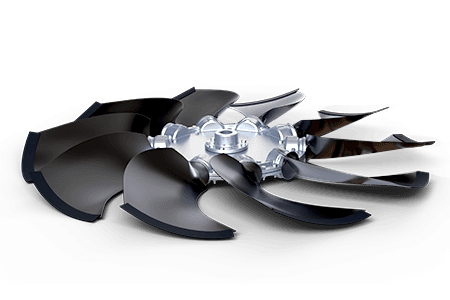

Pre-configured fans

Custom-made fans

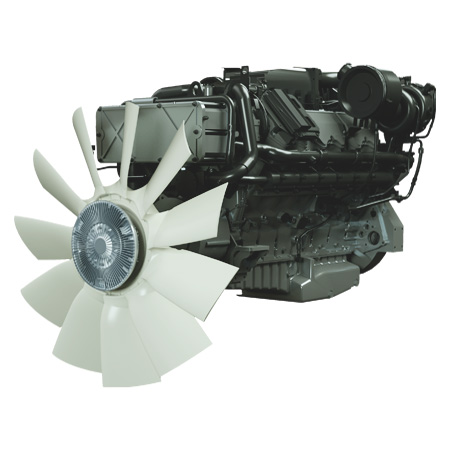

Off-Highway Engine Cooling Solutions: Keeping Your Business Movin

Axial Fans for powertrain cooling

Axial Fans for ICE applications

Axial Fans for battery electric and fuel-cell applications